by B.B. Pelletier

Brian Saade has delivered another great technical guest blog for us. This time, he’s going to discuss metal hardness and how that affects various airgun parts. I can already see the flurry of questions and comments!

If you’d like to write a guest post for this blog, please email us.

Guest bloggers must take clear photos and size them for the internet (if their post requires them), and they must use proper English. We’ll edit each submission, but we won’t work on any submission that contains gross misspellings and/or grammatical errors.

Brian Saade (aka Brian in Idaho)

Metallic Hardness

Now there’s a catchy topic. Hope you had that extra cup of coffee!

Yes, I’m the same guy who recently wrote about the virtues of modern plastics in airguns, so how is it that I’m now writing about the virtues or properties of metallic parts in those same airguns? Truth is, both materials have their place in modern airgun designs and there are many parts inside and outside of our cherished airguns that (still) require metallic designs, not plastics.

Certainly, a rifle barrel is an obvious item that requires fine, high-carbon steel to withstand the rifling process as well as the strain put upon it (think elasticity) during the cocking cycle of a breakbarrel airgun? But, there are other metal parts that we more frequently tinker with or modify on our airguns, and those are most often found in the trigger modules and trigger components.

In both firearms and airguns, we have all heard the terminology associated with certain metal moving parts. Terms such as hardened sear, case-hardened bolt and precision-tempered spring (I’m still baffled by that one, as tempering of steel is as much an art as it is precision). What do all these terms and buzzwords really mean to the average airgun tinkerer or DIY airgunsmith? Let’s explore some metallurgical basics first, and we can then see how they apply to our main interests…argues!

The Rockwell hardness scale

The Rockwell hardness scale

Hardness

In the good old USA, we most often measure surface hardness of steel metals using the Rockwell “C” scale (aka Rc). As an example, a common framing nail nearly falls off the bottom of the scale at a lowly 12 to 15 Rc. Conversely, a finely made steel cutting tool or knife blade could range between 50 and 60 Rc or higher. Drill bits and other high-speed tools range even higher on the Rc scale. I’ve broken many a drill bit and know that the very high hardness also induces brittleness or lack of elasticity and ductility in the metal. Metal parts that bear upon each other or that must withstand wear and strain will typically require some form and level of hardening or hardness.

Case-Hardened

As a kid, I was always in awe of fine pocketknives that claimed to be case-hardened. Not sure why, it just sounded cool. To imagine the case of the metal, think of a piece of round steel bar, say 2 inches in diameter and one foot long, that was case hardened. The surface of that bar or the case is now harder than the interior portion of the bar. This could be up to .125 inches deep from the surface. Case-hardened metals are often used where surface wear is an issue, but the part must also retain inner elastic properties to a greater or lesser degree. In everyday terms, it needs to resist wear and also flex or move within its design purpose. On the opposite end of case-hardened steel is through-hardened. As the term implies, the raw material or finished part is hardened throughout the cross-section of the part, not just on the surface or some depth away from the surface. There are algorithms and Jominy tables and other methods of determining how this is done, but that’s another 10 or 12 pages of rather dry stuff that won’t help you polish that trigger sear in your Crosman 2240! (Yes, there was actually a Dr. Jominy, Ph.D., who designed the Jominy tables for hardening metals. Go figure.)

Tempering

We all recognize this term, whether in metals or in life experiences. “Temper your remarks young man,” our sixth-grade teacher might have said to us back in the day. She was actually saying “restrain yourself.” So, think of tempering (as in tempered springs) as restraint in the metal, or the metal not easily letting loose of its potential, elasticity or memory. Tempering can be achieved through many methods. Quenching in oil or water, air- or vacuum-controlled increases in heat followed by cooling, and hybrids of all the above. Ever heat a tempered spring with a propane torch to try to reshape it or expand the length of a coil? Oops! It’s not very springy anymore! Why? The spring lost its temper (pun intended) when you heated it enough to move the metal. That’s called annealing of the metal or softening and is just the opposite of tempering. That topic would be another 10 or 12 pages and a full pot of coffee, so let’s move on!

So, we now have a few of the basic terms and definitions in grasp, so what about those parts in the trigger we want to tinker with to improve those 10-meter groups at the range?

Trigger sear

Ah, yes, the often maligned trigger sear, the object of our Dremel tool and much debate on the forums and blogs. The part of the trigger set that lets loose of the mainspring or the hammer and sends the pellet on its way. The surface hardness of well-made trigger sears should be in the 45 to 50 Rc range. This is not an empirical statement, as the mating parts in the trigger set require complimentary hardness and the hardness could be lower, but, in higher-quality trigger sets this hardness matching or design of mating part hardness is a key design criterion (e.g., the Rekord triggers found in Weihrauch guns, such as the HW97).

Weihrauch Rekord triggers achieve this in part with hardened steel pins in the trigger that act as bearing surfaces against levers and the sear. In this way, the aluminum trigger does not require the higher hardness level, and the pins can be replaced if needed. Clever Weihrauch guys! When polishing or forming a shape in a trigger sear, use a good stone and oil, much as you would on a fine knife blade. Resist the urge to use the Dremel tool or bench grinder, no matter how fine the grit or wheel. Heat builds up very quickly on these small, steel parts and that heat is the enemy of the surface hardness of that sear. Ever cut down a 10-32 steel screw with a Dremel wheel and (sadly) put your finger on it before it cooled? You get my point, a lot of heat! Likewise, be very cautious in any reshaping of the sear or engagement features. What you may consider as polishing may actually be a relief that lets the sear release prematurely and without notice. Last, as to low-end airguns and some of those of Chinese origin, I can’t speak to their metallurgical skills or desires in making trigger components so, as always, buyer beware.

Bolts

Unlike the trigger components in our airguns, the bolt in an airgun sees little friction or wear, particularly where it meets the very soft lead pellets. In firearms, the bolt is a more complex device with actuators and inner workings and, more importantly, it sees huge pressures and strain from magnum loads. In firearms, the hardening of bolt faces and components is one of the most critical design features in the weapon. For airgunners, the bolt just needs to be hard enough to not wear out, but also not so hard that it wears a groove in that plastic breech that I wrote about a few months ago. However, an airgun bolt such as those found in CO2 guns will have a connection to the cocking mechanism and some bearing surface that rides over or engages the trigger assembly. My old Benji/Sheridan AS392 .22 cal bolt is an example of this type part that rides inside the bolt and requires some level of hardness on its face.

Bolt from my Benjamin AS392

Springs

Temper, temper! This is one component that I seldom home-brew or practice DIY surgery on. With the wealth of spring types, sizes, wire alloys and configurations available to hobbyists like us, it seldom pays off to modify springs other than cutting and cold-forming the ends square and perpendicular. I’m speaking mostly about coiled springs and especially powerplant springs in airguns. Also, keep in mind that heat (above 200-deg. F) is the enemy of the small and usually thin, tempered spring we might find in trigger sets. Careful cold bending at shallow angles or shearing (not grinding) to length or shape is the method of choice for these spring modifications or repairs. As for other types of single- and double-loop springs with tails or flat wire springs found in trigger sets, finding replacement or

alternative springs is not nearly as easy as it is with their coil cousins. However, there are many industrial spring makers out there and a search on the web will produce interesting results for replacements or alternative types of springs. You’ll be surprised at how common that weird looking spring in your trigger may be. Not Home Depot common, but common among industrial designs and spring makers. Keep safety in mind though, as the guy who designed your trigger also calculated the loads and weight of return necessary to actuate the gun and still be safe. Springs are also levers, and as Archimedes said, “give me a lever and…” anyway, always practice safety first in spring replacement or modifications.

Pop quiz: No, but maybe a little summary is in order?

When polishing or improving the finish on trigger sears and parts, keep heat to a minimum and always maintain the flat surfaces and basic shapes that you started with. Use clean, flat stones and fine wet/dry papers and oils to polish. Resist using power tools and rounding off edges.

Cutting or modifying springs: “Don’t lose your temper” is all you need to remember. Temper is lost when heat (or energy induced during stretching) overcomes the elastic memory of the metal. This is very easy to do in small, delicate trigger springs. Cold working and patience is the key.

Safety rules the day. Always think your project through to the end result before starting down the DIY road. Don’t do as I have done in my earlier days and modify everything in sight with no way to tell which mod improved what. Worse yet, having one mod offsetting the benefit of the others and possibly making the gun unsafe. Take incremental steps, especially inside the trigger group and mainspring components or modules.

Hopefully, I’ve armed you with a few bits of new or refreshed knowledge in this report that will help you apply some additional science and a little more precision to your next trigger or spring modification/repair project. Till next time, shoot well and shoot safe!

Nice blog Brian and interesting topic !

Well this is off topic (or not ,after all it is about main spring) question is -how much time can you leave your gun cocked ?My opinion is this ; even 10 min is too much or am i wrong ,i never cock my rifle if i am not ready to shoot immediately !?

That is sure to be controversial.

I have one that has been sitting in the corner for months that is cocked. It is a piece of junk that I consider expendable. I might break it out later this morning to see how it does, then cock it again and put it back in the corner again.

twotalon

I leave mine cocked as much as a half hour at a time. Has not caused me any noticeable problems yet.

I leave my pcp guns cocked much longer at times, but we are talking about hammer springs only here. They are not so heavily compressed that there is going to be any significant damage.

Since I am a hunter, I like to aviod noise and motion. Cocking my 48 right before a shot would not work very well unless my intended target was blind and deaf. I can uncock the 48 if I want to instead of shooting it. Can’t do that with my other springers.

twotalon

I leave my magnum springs cocked for 30 mins very occasionally… I find it smooths out the firing cycle noticeably for several weeks. I also do the same after I oil the compression chamber, about once a year.

To All: Thanks for your kind comments.

g.austin: spring guns that have quality springs and internals should not see any permanent damage from leaving the gun cocked for short periods, even an hour should be fine. My experience is with RWS, Weihrauch and Air Arms guns, and I have done this with all of them. Spring “set” or loss of temper takes a lot of concentrated energy (compressed coils) over extended periods of time. The equation would be different for every size, shape and metallurgy of the spring however, for quality spring guns it would certainly be more than an hour for this de-tempering process to begin. Likewise, a good quality trigger set (springs) should be affected far less if at all (the sear & lever devices are taking the load, not the small springs).

Milan: See my reply to g.austin below, I clicked the wrong reply button!

Mr. B “distemper”? That’s a good one!

Loss of temper do takes a lot of energy 😉 i would know 🙂

Milan,

I did a test called the Mainspring Failure Test, in which I left for different mainsprings cocked for up to one month and tested them at various points along the way. Back before I admitted that I was Tom Gaylord, I reprinted that test in this blog:

/blog/2006/5/how-long-does-a-mainspring-last-part-2/

To answer your question, ten minutes of cocking is NOTHING! A mainspring can tolerate weeks of being cocked before it starts loosing power.

However, don’t just leave it cocked for no good reason. Because all those minutes do add up.

B.B.

Thank you BB, thank you all for answers i didn’t know that.

B.B.,

What about leaving a Nitro Piston cocked for several hours. I was in my hotel when I accidentally broke the barrel too far. Trouble was, it was raining, and I had nowhere to load and shoot it. I eventually found an open area a good distance away from where I was staying.

Are Nitro Pistons more or less sensitive to being left cocked?

Thanks,

Victor

I believe one of the selling points of the nitro piston is that you can leave it cocked indefinitely. So no, I don’t think you hurt anything.

Vince,

Thanks for the answer. Still learning about these things.

Victor

Morning Brian,

Thanks for taking your time writing another blog in your continuing education course for us. Milan and twotalon have brought up an interesting topic. How long can a springer be left cocked without damage to the spring? How is that time related to the temper of the spring?

If a spring isn’t feeling well would you say that it has distemper?

Bruce

I just got out the piece of junk and tested it. Doing about 820fps after being cocked most of a year. I had previously left it cocked for a few months at a time. I am sure that it is slower than it originally was but I did not write down the original velocity.

Most of my springers run in the 850 range with cpl, but I think this one may have been a bit faster out of the box.

Do you know they collect a lot of dust, lint, and cat hair just sitting in the corner that long? Should have set it next to the litter box to get REALLY filthy. Can’t hurt it.

twotalon

Great article Brian… very very helpful to anyone who’s spent time improving the Crosman trigger.

BB actually covered the topic of leaving a spring gun cocked…..I hope I remember correctly.I think

even a worst case scenario was less than 10% loss in velocity.I really apreciate this blog topic.I can relate to the need to protect metal from heat because of all the knives given to me to sharpen…after being ruined on a bench grinder! What an ugly sight that is.I will admit,here and now,that I don’t know enough to work on any trigger more sophisticated than a Crosman 22xx or a Benjamin 39x.I have an enormous respect for anyone who can dis-assemble and improve a complex trigger group! I’ll do my thing and gladly pay them to do theirs for me.Thanks for this blog,some of us need reminding about what we shouldn’t do!

Frank B is right. BB did this experiment in his book on the R1. He left his R1 with either the OEM spring or an aftermarket spring, cocked overnight. When he tested it the next day, it had actually picked up a couple fps.

I also remember reading Jeff Cooper (“Cooper on Handguns” – which was really about the .45 ACP) saying that no harm would occur to your .45 ACP if you left it in the Condition one position (cocked and locked) indefinitely.

Fred PRoNJ

Brian,

Very informative, well written blog! It’s a keeper for sure! …And you were right about that extra cup of coffee, mine hasn’t kicked in yet!

ka

Very well done, Brian!

The discussion on leaving springers cocked reminded me of a discussion I had read on another blog somewhere. The point was made about the similarity between the mainsprings in springers and the valve springs in piston engines. Consider the condition of the valve springs in your car engine when it is stopped at any given time: Some of these springs will be at their most relaxed position (but still under some load, valves closed). Others will be at their most compressed position (valves fully opened), the rest will be somewhere in between. If it damaged these springs to be left in a compressed condition for a matter of hours or longer, then valve spring failure in engines would be common. Instead, it is very uncommon, unless they have been subjected to stress in excess of their designed load. Even then, breakage is more likely to occur elsewhere in the valve train.

I recently started an engine that had sat for three years without being cranked. As soon as the lifters recieved oil pressure, it ran without any excess valve train noise. This should be similar to firing a springer that had been left cocked for three years.

I never leave any sort of gun stored in a cocked condition. The reason has nothing to do with concern for spring life. It is a basic safety issue to me.

Les

Great example Desertdweller

Another would be the coil springs in the old, lift-up garage doors back in the day. Depending on how often the door was opened and closed, that spring could be in the stretched or relaxed position for hours each day and 100’s of days per year(s). Of course, when Stanley Hardware still made springs in the USA, they lasted for decades. When they went the China route (70’s -ish) I can remember replacing two or three springs over 5 or 6 years time.

Les,

Interesting observation on valve springs vs springer springs. I wonder if the length/thickness of a spring makes a difference since valve springs are quite short not to mention pretty thick. Or perhaps the valve spring is a much better quality? Better tempered (is this even possible)? Now I wonder can temper be variable? Can one object be better tempered than another (I resist the opportunity for a corny joke)?

-CJr

Brian,

Again, so much to learn and so little time! This report is a real eye opener for me. I have not considered the seemingly innocent heat being generated as affecting the effects of metal parts. I only assumed excessive surface removal as a culprit.

I wonder now how badly my Dremmel router bit has been damaged by the heat generated by the friction between it and the wood I’m cutting. I wonder now how easy it is to lose temper of cheap router bits by this heat reducing the effectiveness over a short period of use. I know steel is harder than wood but I now wonder if the heat generated by the cutting is causing the steel to dull. Usually during routing the wood and/or bit get so hot that smoke pours from the cutting area.

I also notice that the bit cuts better when it is cold. When it heats up it seems to cut less efficiently. It also seems as if this loss in efficiency is temporary. If I let the bit cool down it seems to cut better again until it heats up. Is this possible or do I imagine this? Does the bit lose temper then regain it again after it cools down?

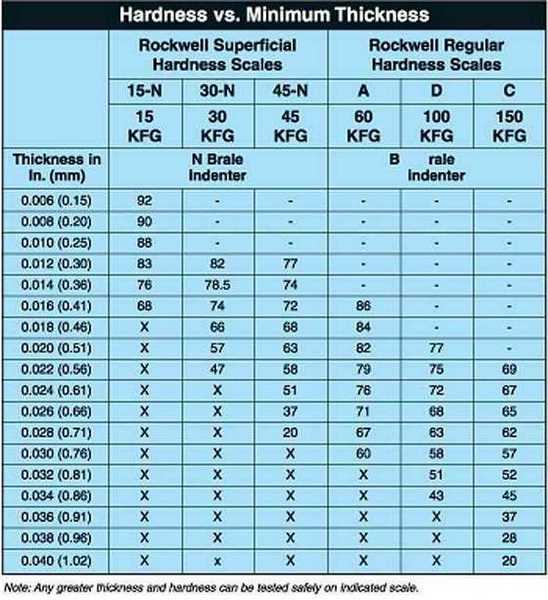

Oh, and another thing, how about another report on how to use that dang table you put at the beginning.

-CJr

Oh Boy! Cutting tool wear and tool MTBF, now that’s a whole volume of stuff!

If the tool bit is actually tungsten-carbon (carbide) then the change in cutting behavior is more the nature of the wood surface changing under heat than any change to the tool. In woods that have high oils or saps, it’s more of a guminess or coating of the tool. It’s not likely that wood cutting (alone) would actually alter the surface characteristics of a good, carbide bit but… the wood will wear the bit at the contact points over time (flutes or cross-hatches etc) which is a slightly different process of degradation or actual metal removal.

We see this in metal cutting to some degree also. 316 stainless doesn’t chip or make flakes as you cut, it makes shreds or curls. We call it “gummy” as compared to 17-4PH stainless or others.

Back on my China rant, the bulk of the Big-box store tools are of the Chinese persuasion, even Stanley. Basically, they are mostly garbage.

Brian,

Thanks very much for presenting a complex subject in a straightforward manner. Well done!

I must agree that the quality of the steel and/or steel alloy from offshore sources is definitely a buyer-beware situation, especially with “non-branded” products. I bought a cheap set of S&D style big diameter twist drills to have on hand for occasional use. The ones that came sharpened correctly worked OK for a while, but resharpening immediately revealed that what seemed to be a black oxide finish on reasonable quality high-speed or high-carbon steel, was just a thin case hardened surface on a low carbon steel. As soon as I cut through the case, the drill was about as hard as the framing nails you mentioned. You get what you pay for, sometimes!

Lloyd

Thanks lloyd.

Yup, so much of the tooling out there today is real garrrrbage.

A lot of the plain twist drills are just carburized steel and are basically worthless after one or two uses in tough or hardened metals. The black oxide is just to stop rust and is nearly immeasurable as to it’s thickness, its a deposition not a coating really and should actually be oiled to remain useful.

I have some cheap sets that are hardly able to drill wood yet they look new!

Edith warned me about that table and like a good man, I didn’t listen!

Here’s a link to an old SAE table that gives RC as compared to other hardness scales like Brinnell. The lower the Rc number, the softer the materials surface.

http://emat.eng.hmc.edu/database/rockwell_conversion.htm

As to scale or use of the table, just think of the common framing nail being down below the 20 Rc mark, a good trigger sear being about 40-ish Rc and your hardened tool bits or drills heading up to 60 Rc or more.

Brian,

Thanks for the table link. Unfortunately, after seeing it, I now have to wear a much larger Stupid-Hat.

🙂

-CJr

Brian,

Thanks for putting this together, interesting reading. I don’t agree that a barrel needs to be “fine, high-carbon steel”: brass, iron and soft steel can all be used in airgun and some firearms applications, although I do get your point about the mechanical requirements for breakbarrels.

On the spring compression (leaving gun cocked), its just another airgunning tempest in a teapot, in my opinion. Probably you’d lose the same amount of power over the same period of time using it normally. I don’t have the R1 book, but I don’t remember there being a control springer for each spring tested. That is to say, how do we know that the springs wouldn’t have lost the same amount of power over the same period if used normally.

Yes, the point was a barrel also used as a long lever on a springer. My EB .22 Co2 pistol has a bronze barrel that works just fine soldered to the frame!

I had a similar thought on the mean time between failure (MTBF) for any given spring as it actuates or works in service. My only measure of this is my HW97K going on 7 years old and about 5000+ rounds, still cranking out 870+ fps and was 880-ish when new. Then again, I’m an oil & maintenance guy on all my spring guns.

BG_Farmer,

The control was that I tested the factory HW mainspring that came with the R1. So there was a control.

B.B.

CJr,

I don’t know about quality of engine valve springs vs. springer springs. I do know that shorter springs are stiffer than longer springs, everything else being equal. I believe that is a matter of leverage.

I have a friend who worked in the spring-winding business. I’l try to remember to ask him.

I do remember from when I worked with Ford, there were a number of different springs available (and interchangeable) for FE series V8 engines. There were at least two wire thicknesses available, plus a racing variation that contained a second spring inside of the primary spring. The heavy springs were meant to prevent valve “float” at high rpm.

I would assume engine valve springs would be treated to withstand prolonged exposure to high temperatures.

Les

Brian,

I have a comment on springs being kept under compression for an extended period of time. The magazines for my Browning High Power have been loaded continuously since 1969. I don’t know how old the gun or the magazines actually are since I picked them up while I was in Viet Nam. The only time they haven’t been loaded is when they’ve be shot to empty. They are still working perfectly.

Bruce

PS A HEART FELT THANKS TO ALL OF YOU WHO SERVED.

Mr B same here, I have 45 ACP mags that are always loaded and they are as stiff to load as they were new, years ago! One of those 45’s came home with me from Vietnam, as did your Hi-Power. Semper Fi.

Springs and tempered steels can be marvelous tools when done right. That’s why I agree with BGFarmer about the “tempest in a teapot” around spring guns being left cocked. As BB also noted, he tested for days and weeks on several spring guns and found no huge issue or degradation in the guns performance.

Spring failure is death by a MILLION cuts, to paraphrase the Bard. All springs will someday fail but, is that after 1000 cycles, 100,000 cycles, or more? For me, my HW97 has seen well over 5000 rounds and with my infamous accuracy, that is probably 8000 cocking cycles. The velocity has decreased less than 8% since new and I just regained 11 fps with new breech seals last week. Even then, I can’t directly attribute the small velocity loss directly to the mainspring, and after changing the seal, that is confirmed for me. I would like to be able to predict the springs life cycle or failure point but, my guess is, that it will just fail completely some day with no early warning or gradual loss of effectiveness. That’s just the nature of tempered steels made into springs.

In the meantime, lots of maintenance and TLC on my spring guns and when the day comes, I’ll go get a new spring!

Brian,

From what I garther, you should not grind the end of a spring which was cut to get it square? If you did, must you then temper the spring to regain the properties which were lost due to heat generated during grinding?

Ton, as slow and tedious as it may be, slow cold bending (repeated small bends) and filing to shape are the best methods to dress the spring ends. Having said that, if you must use a grinder, have a small pot of 30 wt oil to quench it in as you go A little grinding,dip in the oil and repeat. It takes longer but the results are that you will retain a large percentage of the original temper at the end coils and the flats.

I have seen springs and other devices that were ground to shape quickly / vigorously and after seeing them in service, the ground ends bowed or collapsed or otherwise distorted. Also, keep in mind that most springs are high carbon steels by nature and carbon precipitates or moves under heat and stress. That is what we might call a hard-spot in a steel form, and hard spots are potential crack zones. The surrounding areas that “lost” their share of carbon are weakened at the same time.

Before the clock turns the hour let me share Good Wishes this Veteran’s Day to my fellow Veteran’s and Their Families.

To any military & retirees that may not know it I recently found out that most Lowe’s and Home Depot Stores offer a daily military discount. Sad part, I called Lowe’s Headquarters and was told it was not corporate policy to advertise a discount except on military holiday’s! I’ve spent several thousand dollars there and never knew about it. To make it more insulting I normally wear a NAVY VETERAN ballcap so I would think the cashier would have mentioned the discount. I don’t know if every Lowe’s and Home Depot offer the discount, but I live in Georgia and my parents (dad army vet) live in New York and we get discounts. It never hurts to ask.

Just passing on some info.

rikib